Home > Installation

CLIMATE CONDITION:

Install the PV module in the following conditions:

Ambient temperature : -20℃ to + 40℃

Operating temperature: -20℃ to + 80℃

Snowfall pressure : below 2000pa

Water resistance : don’t install the PV module in a location where it would be immersed in water or continually exposed to water from a sprinkler or fountain etc.

ORIENTATION:

Install the PV modules facing South (in Northern Hemisphere),or to North (in Southern Hemisphere),incorrect orientation will result in loss of power output.

PV modules connected in series be installed at same orientation and angle(generally south by west 10 degrees and the horizontal angle is the local latitude plus 5 degrees).different orientation or angle may cause loss of output power due to different of amount of sunlight exposed to the module.

Install the PV as free as possible from shading. Shading causes loss of output, even though the factory fitted bypass diode of the Pv module will minimize any such loss.

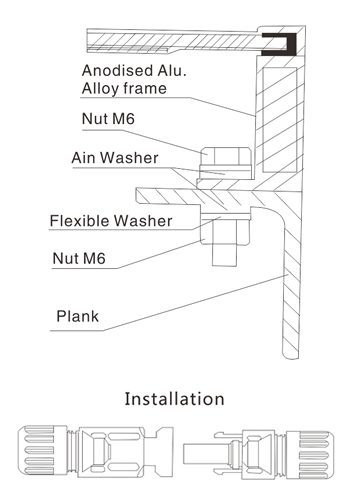

INSTALLATION:

Using spring washers and flat washers to fasten the PV module to shelf.

Using spring washers and flat washers to fasten the PV module to shelf.

Ground the PV module properly in accordance with mounting structure and environment.

Note: not install the PV module near naked flame or flammable materials.

Mounting structure should wiht stand forces from wind pressure and snowfall pressure etc.

Use appropriate methods to mount PV module near naked flame or and flammable materials.

Mounting structure should withstand environment. Select proper materials and corrosive treatment.

Use appropiate methods to mount PV modules. Fall or modules from high place will cause death, injury or damage.

Do not disassemble, bend, impact by sharp objects, walk on,and throw or drop etc.

WIRING AND NOTES:

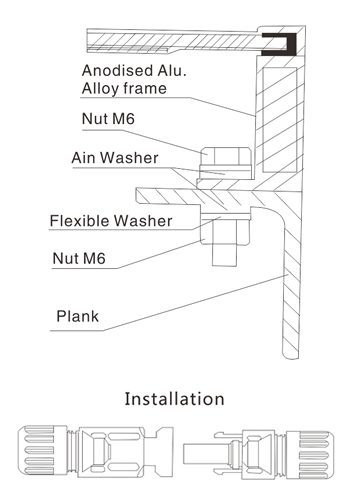

The PV module has a pair of male and female waterproof connectors. For a series electrical connection, connection, connect postive(+)connector of the first PV module to the negative(-)connector of the following module.

Connect the output cable with equipment correctly.

The connectors and wites should be what our company provides.

Do not short the posiive and the negative.

Be sure connector no gap between the insulators. In case there is a gap, a fire and/or an electrical shock may occur.

.

MAINTENANCE:

Check if mounting structure is loose..Tighten the loose components again, if required.

Check connections of cables, grounding cables and connectors.

Clean the face often with soft cloth etc.

Changed module must be the same kind and type.

Do not touch live parts of cables and connectors. Use appropriate safety equipment(insulated tools, insulating gloves, etc.)when touching them.

Cover the front surface of the PV module by an opaque cloth or other material when repairing. The PV modules when exposed to sunlight generate high voltage high voltage and are dangerous.

.

QUALITY ASSURANCE:

The quality assurance time of the PV modules is five years. The power declines not exceed 10% in ten years and 20% in twenty-five years. .

Install the PV module in the following conditions:

Ambient temperature : -20℃ to + 40℃

Operating temperature: -20℃ to + 80℃

Snowfall pressure : below 2000pa

Water resistance : don’t install the PV module in a location where it would be immersed in water or continually exposed to water from a sprinkler or fountain etc.

ORIENTATION:

Install the PV modules facing South (in Northern Hemisphere),or to North (in Southern Hemisphere),incorrect orientation will result in loss of power output.

PV modules connected in series be installed at same orientation and angle(generally south by west 10 degrees and the horizontal angle is the local latitude plus 5 degrees).different orientation or angle may cause loss of output power due to different of amount of sunlight exposed to the module.

Install the PV as free as possible from shading. Shading causes loss of output, even though the factory fitted bypass diode of the Pv module will minimize any such loss.

INSTALLATION:

Using spring washers and flat washers to fasten the PV module to shelf.

Using spring washers and flat washers to fasten the PV module to shelf.Ground the PV module properly in accordance with mounting structure and environment.

Note: not install the PV module near naked flame or flammable materials.

Mounting structure should wiht stand forces from wind pressure and snowfall pressure etc.

Use appropriate methods to mount PV module near naked flame or and flammable materials.

Mounting structure should withstand environment. Select proper materials and corrosive treatment.

Use appropiate methods to mount PV modules. Fall or modules from high place will cause death, injury or damage.

Do not disassemble, bend, impact by sharp objects, walk on,and throw or drop etc.

WIRING AND NOTES:

The PV module has a pair of male and female waterproof connectors. For a series electrical connection, connection, connect postive(+)connector of the first PV module to the negative(-)connector of the following module.

Connect the output cable with equipment correctly.

The connectors and wites should be what our company provides.

Do not short the posiive and the negative.

Be sure connector no gap between the insulators. In case there is a gap, a fire and/or an electrical shock may occur.

.

MAINTENANCE:

Check if mounting structure is loose..Tighten the loose components again, if required.

Check connections of cables, grounding cables and connectors.

Clean the face often with soft cloth etc.

Changed module must be the same kind and type.

Do not touch live parts of cables and connectors. Use appropriate safety equipment(insulated tools, insulating gloves, etc.)when touching them.

Cover the front surface of the PV module by an opaque cloth or other material when repairing. The PV modules when exposed to sunlight generate high voltage high voltage and are dangerous.

.

QUALITY ASSURANCE:

The quality assurance time of the PV modules is five years. The power declines not exceed 10% in ten years and 20% in twenty-five years. .